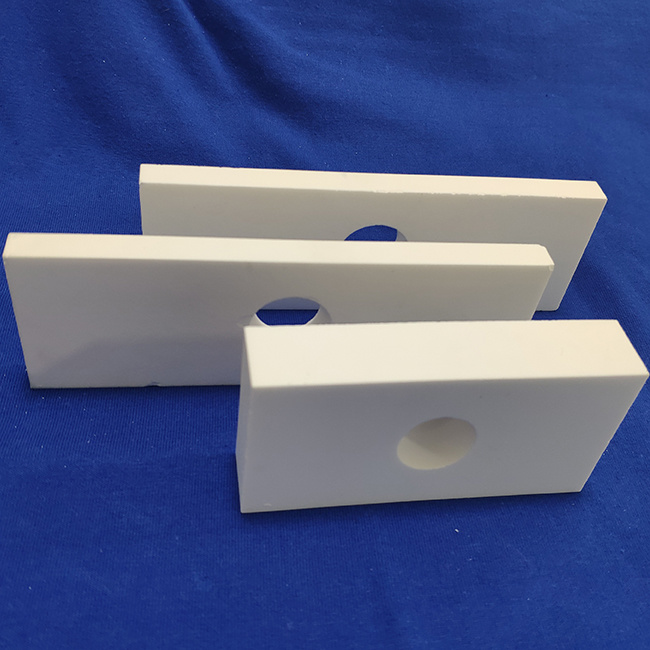

The welded wear-resistant ceramic lining is designed by repeated communication between the R&D personnel and the on-site construction personnel to hollow out one or more conical holes in the middle of the ceramic plate, and the function of this conical round hole is to connect the porcelain plate with the working surface through the electric welding process, and the lining plate is fixed by first sticking and then welding.

Features of welded wear-resistant ceramic liners:

One: high-temperature resistant environment, ordinary adhesive liner generally works at about 100 degrees, even if the use of high-temperature glue can only work at about 300 degrees, but the use of this welding wear-resistant ceramic liner can withstand higher temperatures, greatly broadening the scope of his use.

Two: more impact resistance, the adhesion of ceramic glue is limited, if it works for a long time in a vibration environment, it is easy to fall off. However, welding wear-resistant ceramic liners is first glued and then welded, which greatly enhances the impact resistance.

Welding wear-resistant ceramic lining plate use: is the oil, mining, steel mill, power plant and other industries of material transportation equipment or liquid flow through the surface of the pipeline wear-resistant materials, the main role is to effectively resist the impact of the material on the pipe wall, the corrosion of chemicals and the thermal shock of the material through the material, reduce the wear and tear of the equipment components, thereby greatly reducing the cost of frequent maintenance, prolong the service life of the equipment, is a good choice for industrial wear-resistant, impact-resistant, corrosion-resistant materials.

CopyRigth © 2024 Keystone New Material All Rights Reserved.

鲁ICP备2022031170号-1

Links:

晟通网络